Product

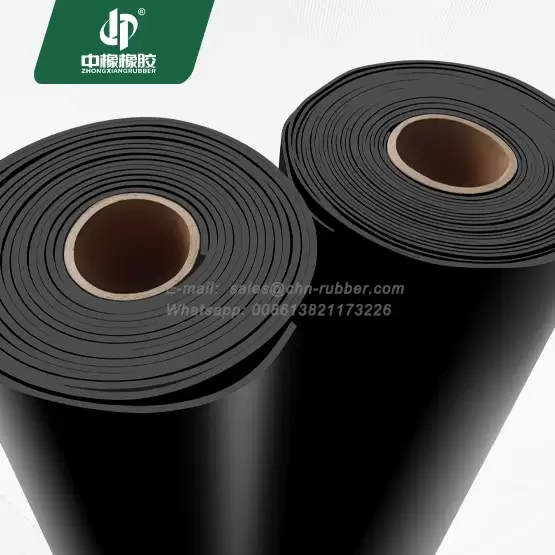

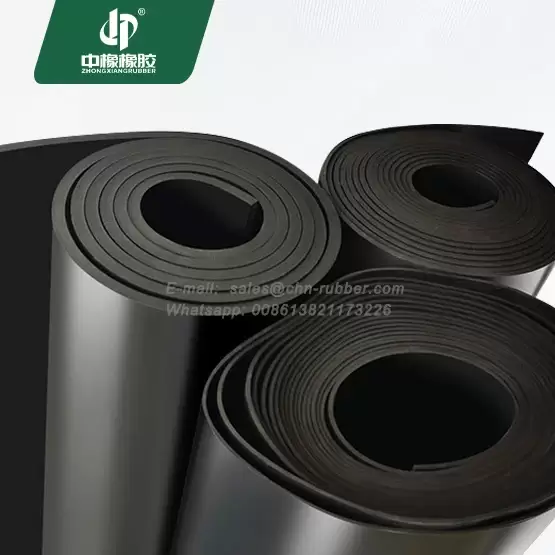

Hardness 60 Black EPDM rubber roll gasket material

Polymer: EPDM rubber

Color: Black / Red / Green; Custom

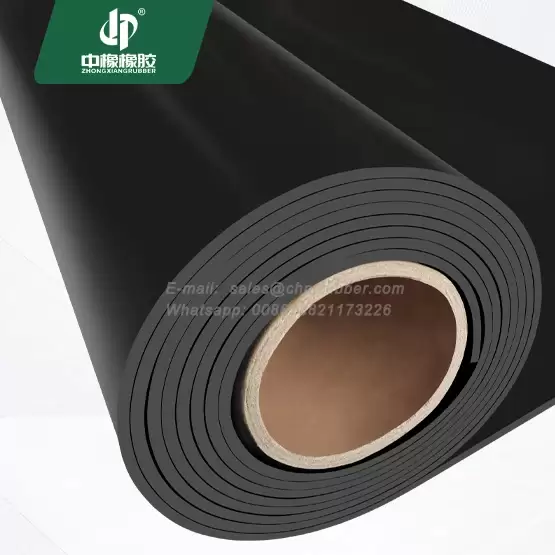

Thickness: Thickness ranges from 1mm to 100mm; above 15mm offered in sheet form.

Standard Size:

Width: 1mtrs 1.2mtrs 1.4mtrs 1.5mtrs 1.6mtrs 1.8mtrs 2.0mtrs

Length: 5mtrs 10mtrs 15mtrs 20mtrs; Custom dimensions available upon request.

Surface: Both sides smooth, or one/both sides with cloth, or one side with anti-slip texture.

Customizable Shapes: Roll / Sheet / Strip

Embedding layer: Nylon canvas / Mesh fabric / Nylon mesh fabric / Encrypted canvas

Packing Info: Custom packing includes plastic film, PP bags, and pallets.

Color, logo, and labels or special markings can be customized upon request.

EPDM Rubber Roll Performance Parameters & Specification

| Code | Specific Gravity | Hardness | Tensile Strength | Elongation at Break |

| ZXZRS20101E-70 | 1.6g/cm³ | 70+/-5 Shore A | 2.5-3Mpa | 180% |

| Thickness | Width | Length | Insertion | Weight |

| 1 | 1.5m | 10m | / | 19.2kgs/m² |

| 1.5 | 1.5m | 10m | / | 31.2kgs/m² |

| 2 | 1.5m | 10m | 1PLY | 43.2kgs/m² |

| 3 | 1.5m | 10m | 1PLY | 67.2kgs/m² |

| 4 | 1.5m | 10m | 1PLY | 91.2kgs/m² |

| 5 | 1.5m | 10m | 2PLY | 115.2kgs/m² |

| 6 | 1.5m | 10m | 3PLY | 139.2kgs/m² |

| 8 | 1.5m | 10m | 4PLY | 187.2kgs/m² |

| 10 | 1.5m | 10m | 5PLY | 240kgs/m² |

| 12 | 1m | 2m | 8PLY | 38.4kgs/m² |

| 15 | 1m | 2m | 10PLY | 48kgs/m² |

| 20 | 1m | 2m | 10PLY | 64kgs/m² |

| 25 | 1m | 2m | 10PLY | 80kgs/m² |

1. All specifications and dimensions above are subject to standard ± tolerances.

2. All data are provided as typical values within specified ranges; actual available specifications may vary depending on standard production grades.

3. This data sheet applies only to the rubber sheet products listed in the table. Other specifications can be manufactured upon request.

4. The weights provided in the table are theoretical values, actual product weights may vary due to production tolerances. In the case of customized rubber sheets, variations in width, length, thickness, or other specified parameters will impact the final weight. For reference only.

Chemical Properties

| Polymer Content | ZXZRS20001PC-20% | ZXZRS20001PC-30% | ZXZRS20001PC-50% | ZXZRS20001PC-70% | ZXZRS20001PC-100% |

| Aliphatic Hydrocarbons | Regular | Regular | Regular | Regular | Regular |

| Aromatic Hydrocarbons | Regular | Regular | Regular | Regular | Regular |

| Lubricating Oils | Regular | --- | Regular | Regular | Regular |

| Outdoor Exposure | Regular | Excellent | Excellent | Excellent | Excellent |

| Ozone Exposure | Regular | Excellent | Excellent | Excellent | Excellent |

| Diluted Acids | Regular | Excellent | Excellent | Excellent | Excellent |

| Diluted Alkali | Regular | Regular | Regular | Regular | Excellent |

| Vegitable Oil | Regular | Regular | Regular | Regular | Regular |

| Animal Oil | Regular | Regular | Regular | Regular | Regular |

Note:

1. The chemical resistance values provided are intended as general reference only, based on standard laboratory conditions.

2. Actual performance may vary depending on chemical concentration, temperature, exposure time, and specific working conditions.

3. It is the responsibility of the user to verify material compatibility before application.

4. The manufacturer assumes no liability for damages or failures resulting from improper material selection or usage conditions.

5. Detailed technical advice are available upon request.

EPDM rubber roll with a specific gravity of 1.6 and hardness of 70 Shore A offers a dependable option for applications requiring strong performance in outdoor and industrial environments. This material exhibits stable mechanical properties and excellent elasticity, even in harsh temperature fluctuations and UV-heavy settings. It performs well in gaskets, insulation pads, and seals across construction, HVAC, and electrical industries.

With its tight molecular structure, the roll provides increased resistance to weathering, ozone exposure, and general aging. It's particularly suitable for environments involving moisture, vapor, and light acids or alkalis. The surface maintains consistency across large roll lengths, enabling easy processing or conversion into various formats like strips or pads.

Contact Person: Carrie Kang

Tel:+8613821173226

E-mail: sales@chn-rubber.com

Wechat: 008613821173226

Whatsapp: 008613821173226