Rubber mat factory is no longer just a production workshop that presses rubber into sheets. In today’s global supply chain, it is a highly engineered manufacturing environment integrating material science, precision equipment, and strict quality assurance. As industries such as manufacturing, agriculture, construction, transportation, and sports facilities continue to demand stronger and safer matting solutions, the role of a professional factory becomes more essential than ever.

A modern rubber mat factory relies on:

- Internal mixers or open mills for thorough compounding

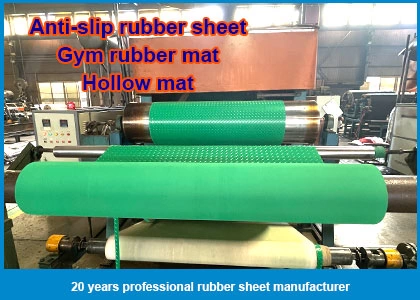

- Calendaring or compression molding equipment to achieve uniform thickness

- Texturing and patterning systems for anti-slip surfaces

- High-capacity vulcanization lines that stabilize elasticity, hardness, and tensile properties

These processes ensure the mats maintain reliable anti-slip performance, cushioning, and wear resistance even under heavy-duty conditions.

Depending on the industry it serves, a factory can produce:

- Industrial anti-fatigue mats

- Gym and fitness rubber mats

- Agricultural and livestock flooring

- Oil-resistant rubber mats for workshops

- Electrical insulation mats

- Heavy-duty protective sheets for mining or transportation

The diversity of applications drives manufacturers to maintain flexible production systems and continuous R&D investment.

Quality and Safety Standards

True industry-grade rubber mats depend on physical testing, not only on appearances. A capable rubber mat factory performs:

Tensile and elongation tests

Abrasion resistance measurement

Shore A hardness control

Aging and ozone exposure tests

Slip resistance evaluation

These controls ensure that the mats will not crack, harden, or lose grip when exposed to real-world stress.